-

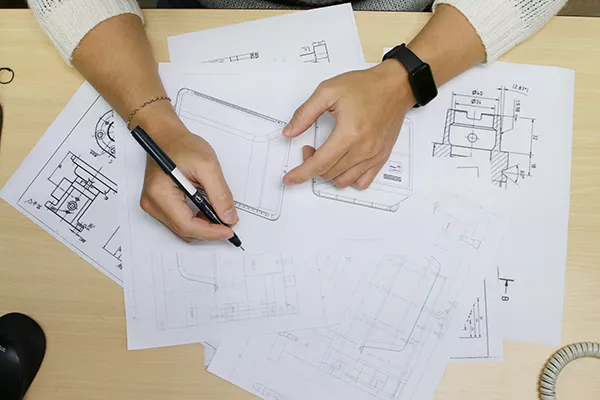

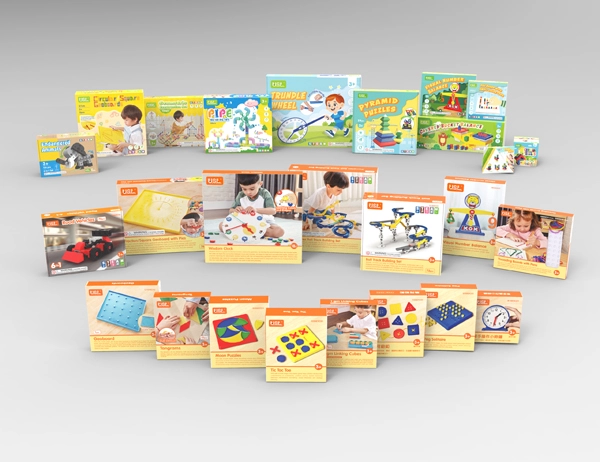

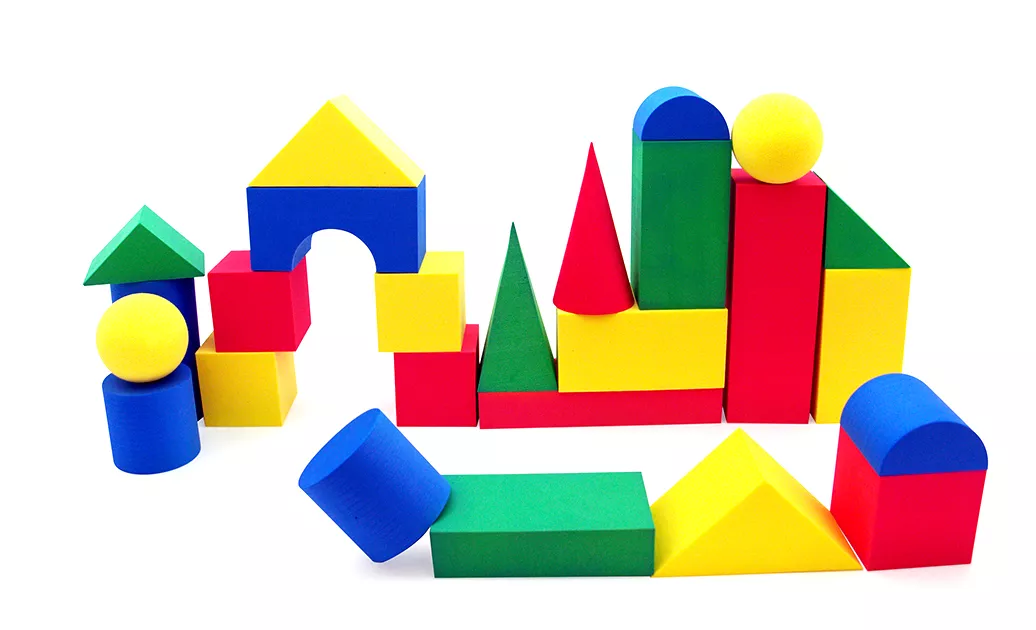

Product Design and Development

Product Design and DevelopmentWe turn your ideas into ready-to-produce toys with prototyping, 3D modeling, and toy-safe material guidance—streamlining development. -

Mold Design and Manufacture

Mold Design and ManufactureIn-house custom mold making ensures accuracy, consistency, and faster lead times for smoother production. -

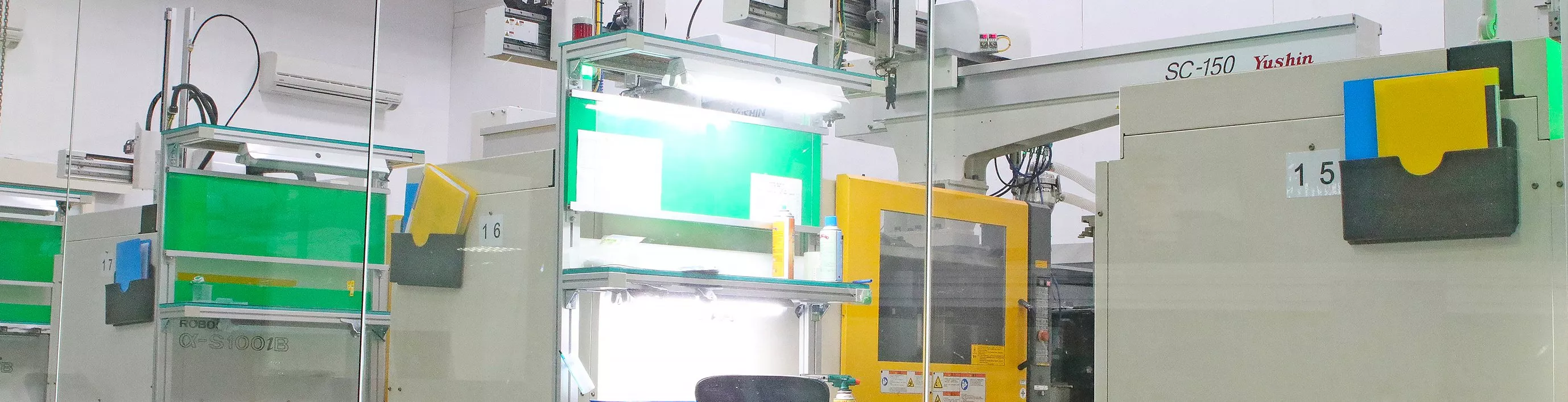

Plastic Fabrication

Plastic FabricationWe offer toy-grade plastics and molding methods to meet durability, safety, and design needs. -

Packaging Development

Packaging DevelopmentCustom packaging solutions that balance protection, branding, and cost—sustainable options available. -

Packaging and Labeling

Packaging and LabelingWe handle barcodes, inserts, and labels to meet global compliance and retail standards. -

Quality Inspections and Shipping

Quality Inspections and ShippingStrict inspections and flexible global shipping ensure reliable, on-time delivery.

-

Colorimeter

Colorimeter✔ Guarantees color consistency in every batch—key for learning-based play.

✔ Builds brand trust with reliable, retail-ready quality. -

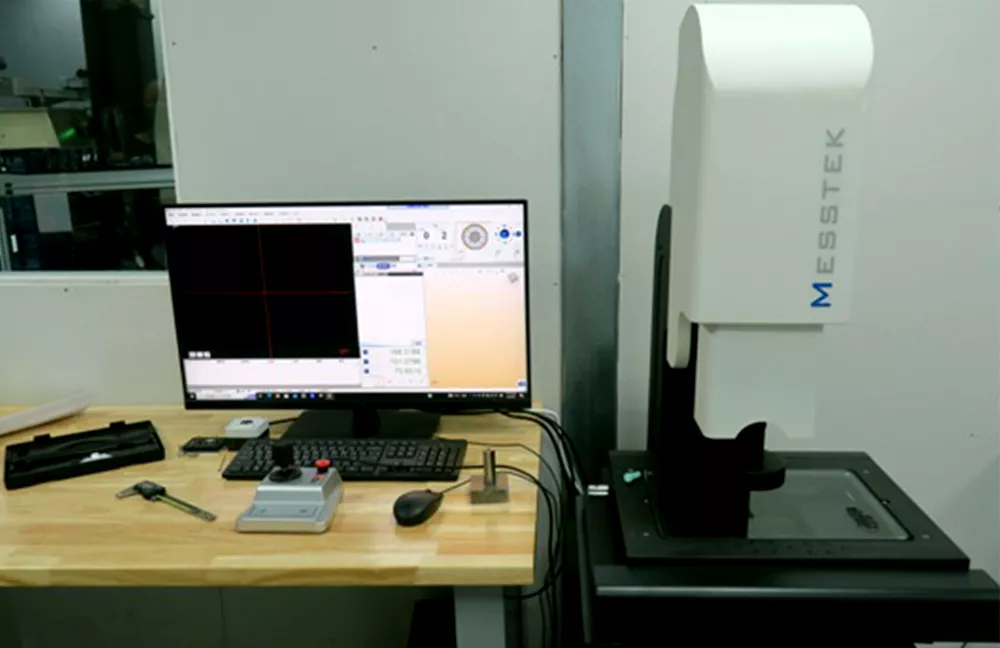

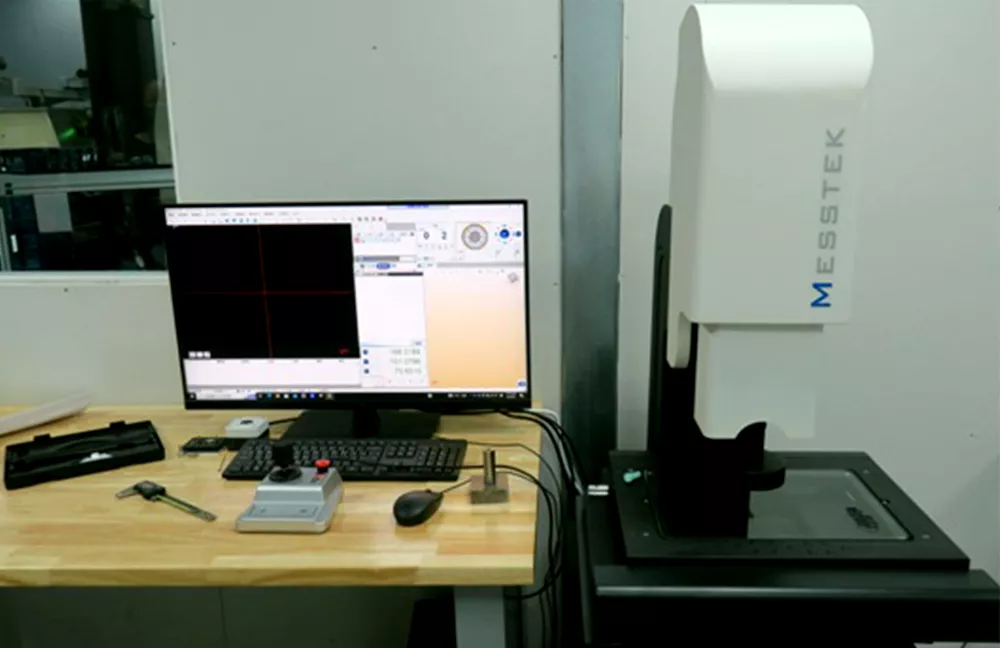

2.5D Projector

2.5D Projector✔ Ensures every piece fits perfectly—no loose or frustrating joins.

✔ Protects your product integrity and user experience. -

Height Gauge

Height Gauge✔ Confirms precise dimensions for stacking, sorting, and matching.

✔ Prevents costly errors and maintains educational function. -

Push Pull Machine

Push Pull Machine✔ Validates strength and safety under real play conditions.

✔ Meets global standards—ready for export and classroom use.

-

(General Plastic) HiPS、ABS、 PP、PE

(General Plastic) HiPS、ABS、 PP、PE -

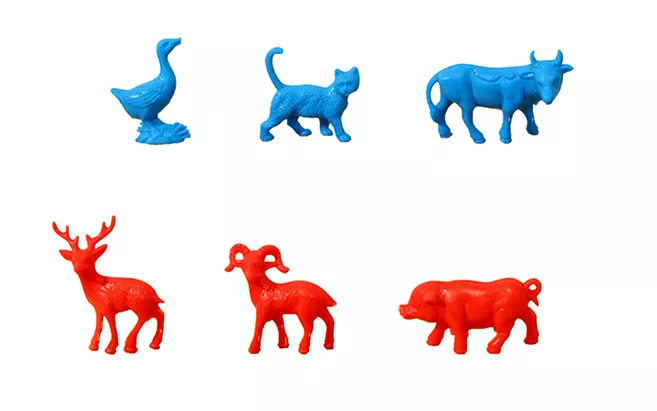

(Soft Plastic) TPR

(Soft Plastic) TPR -

(Hollow Molding) HDPE、LDPE

(Hollow Molding) HDPE、LDPE -

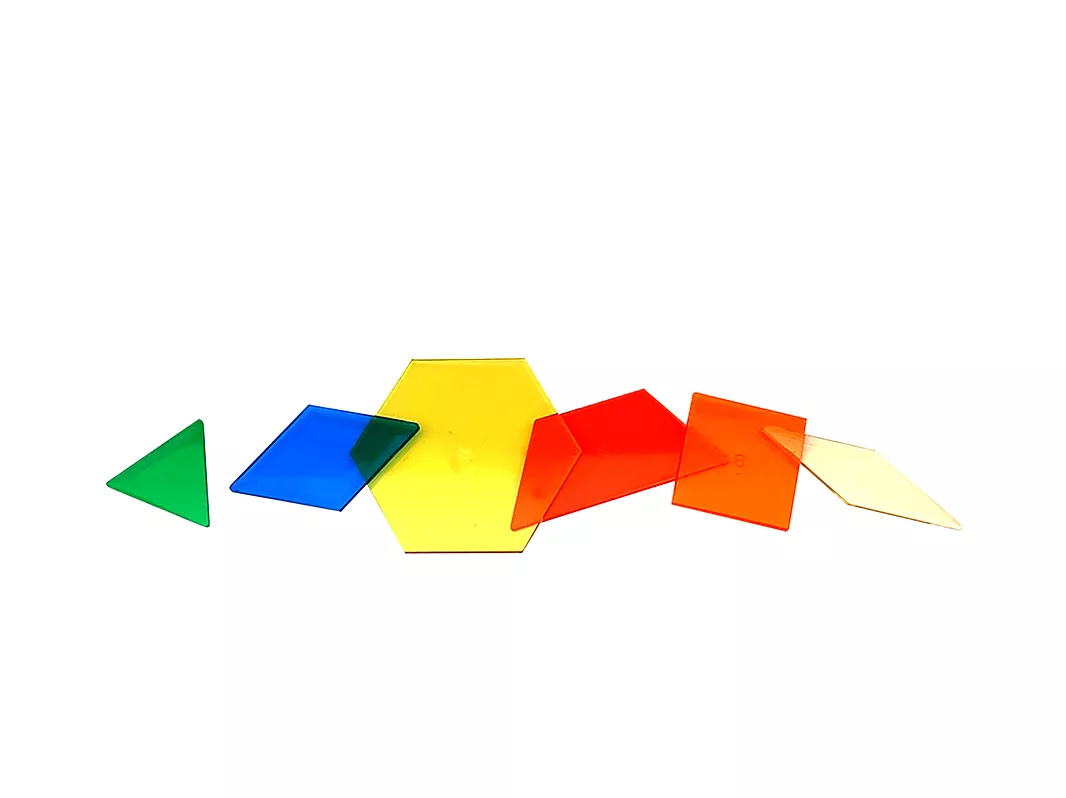

(Transparent Plastic) PS

(Transparent Plastic) PS -

(Foam Padding) EVA

(Foam Padding) EVA

Looking for a reliable OEM/ODM partner? We've been helping brands bring ideas to life for over 35 years. From design to delivery, we offer one-stop manufacturing solutions with ISO 9001-certified quality, eco-friendly materials like GRS plastics and FSC® packaging, and ethical practices you can trust.

All manufacturing at Youth Toy follows ISO 9001 standards and has passed Sedex Ethical Trade Audits.

General Plastic: HiPS、ABS、 PP、PE

Soft Plastic: TPR

Hollow Molding: HDPE、LDPE

Transparent Plastic: PS

Foam Padding: EVA

Materials at Youth Toy for safe, creative production.

Lorem Ipsum

Lorem Ipsum is simply dummy text. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

Colorimeter

- Guarantees color consistency in every batch—key for learning-based play.

- Builds brand trust with reliable, retail-ready quality.

2.5D Projector

- Ensures every piece fits perfectly—no loose or frustrating joins.

- Protects your product integrity and user experience.

Height Gauge

- Confirms precise dimensions for stacking, sorting, and matching.

- Prevents costly errors and maintains educational function.

Push Pull Machine

- Validates strength and safety under real play conditions.

- Meets global standards—ready for export and classroom use.

Beautiful Content. Responsive.

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Lorem Ipsum is Simply

Lorem Ipsum is simply dummy text

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Vivamus leo ante, consectetur sit amet vulputate vel, dapibus sit amet lectus.