Overview of Plastic Toy Manufacturing

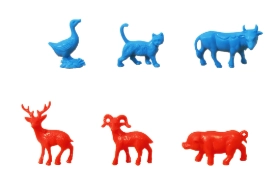

From the toys that fuel a child's imagination to those that support learning in schools, plastic toys are everywhere. But have you ever wondered what goes into making them? For wholesalers, brand owners, and distributors seeking reliable plastic toys manufacturers, understanding the process—from material selection to molding and safety testing—is critical to choosing the right partners.

Explore our wholesale toys.

Key Plastic Toy Materials

Types of Plastic Used in Toys

Plastic toys are made from a variety of polymers, each chosen based on the product's intended use, safety requirements, and durability. The most commonly used materials include: Polypropylene (PP), Polyethylene (PE), ABS, and TPR.

Properties of Each Material

Choosing the right plastic toy materials is not just about cost—it's about function and safety. ABS ensures excellent plastic durability for structural strength and frequent handling.

Choosing the right plastic toy materials is not just about cost—it's about function and safety. ABS ensures excellent plastic durability for structural strength and frequent handling.

General Plastic: HiPS、ABS、 PP

Soft Plastic: TPR

Hollow Molding: PE

Transparent Plastic: PS

Foam Padding: EVA

Explore our Toy OEM & ODM Solutions.

The Plastic Toy Molding Process

Injection molding involves injecting melted plastic into a steel mold cavity. This is the most widely used method by plastic toys manufacturers. Blow molding is used for hollow toys, and rotational molding is ideal for larger, seamless items.

See how we bring ideas to life—Check out our plastic toy molding process in action.

Ensuring Toy Safety Standards

Compliance with toy safety standards like ASTM F963 and EN71 ensures non-toxic and hazard-free products. Share your expectations with the manufacturer to make sure they maintain strict quality control—from raw materials to the final product.

Inbound Inspection

Manufacturing Inspection

Product Inspection

Youth Toy ensures uncompromising quality at every stage of production.

Evaluating Plastic Durability and Safety

Safe toys begin with safe materials. For instance, Youth Toy ensures all components are free from phthalates, BPA, and lead. Our products are reinforced for long-term plastic durability and performance.

Examples of Our Tools for Ensuring Safety and Precision.

Conclusion

The success of plastic toy production relies on selecting the right materials and molding techniques. Safety and quality standards are essential, especially for educational use and discerning distributors. Youth Toy empowers you to build lasting brand trust through precision, compliance, and quality craftsmanship.

Have a project in mind?